To keep your ice cream business running smoothly, focus on key parts like the compressor, beater blades, thermostat, seals, and dispensing valves. Regularly check and maintain these components to prevent breakdowns, guarantee consistent quality, and avoid costly repairs. Dull blades, faulty thermostats, or leaks can cause problems that hurt your customer experience. Proper maintenance of these essential parts can save your business time and money—discover how to keep everything in top shape.

Key Takeaways

- Regular maintenance of the compressor prevents costly breakdowns and extends machine lifespan.

- Ensuring the beater blade is clean and sharp maintains product quality and reduces strain on the machine.

- Proper calibration of the thermostat guarantees consistent ice cream texture and prevents spoilage.

- Replacing seals and gaskets promptly avoids leaks, contamination, and expensive repairs.

- Consistently updating the dispensing valve minimizes clogs and downtime, ensuring continuous service and customer satisfaction.

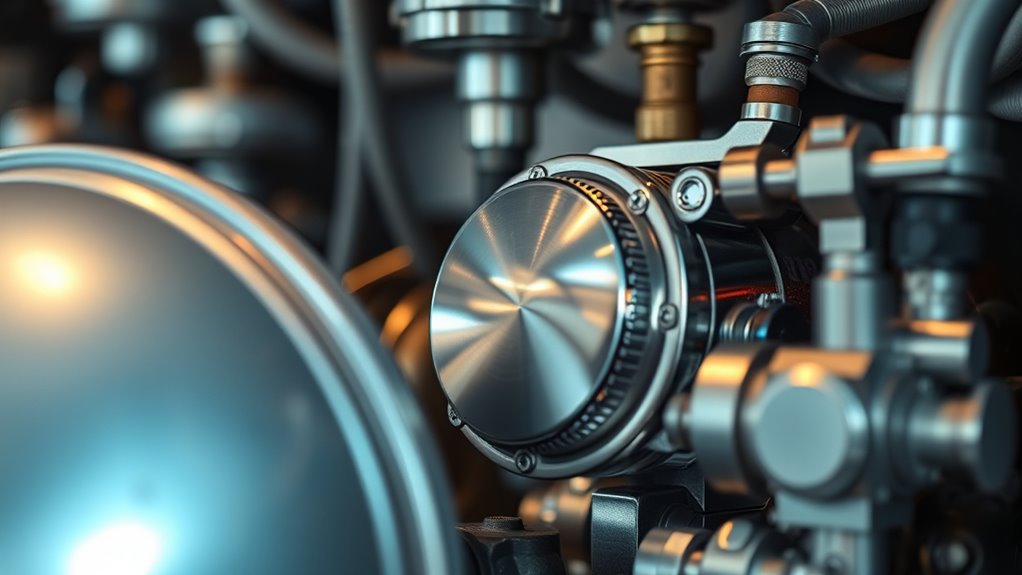

The Importance of the Compressor in Ice Cream Machines

The compressor plays a crucial role in your ice cream machine by transforming refrigerant gas into a high-pressure, high-temperature state. Proper maintenance tips are essential to keep it running smoothly; regularly check for leaks, clean the filters, and ensure proper oil levels. When troubleshooting techniques are needed, listen for unusual noises or notice a decline in cooling efficiency, which could indicate a compressor issue. If you encounter these problems, avoid attempting repairs yourself—call a professional. Keeping the compressor well-maintained not only prolongs its lifespan but also prevents costly breakdowns. Staying proactive with maintenance tips and troubleshooting techniques helps ensure your ice cream machine operates reliably, delivering consistent quality and preventing downtime during busy seasons. Additionally, understanding the refrigeration cycle can help you better diagnose and address potential problems before they escalate. Recognizing the importance of regular inspections can further prevent unexpected failures and maintain optimal performance. Being aware of the automation in refrigeration systems also allows for better integration of modern monitoring tools to detect issues early. Regular performance evaluations can also identify wear and tear before they cause significant damage, ensuring continuous operation.

How the Beater Blade Ensures Smooth Operations

Since the beater blade directly interacts with the mixture inside your ice cream machine, its design and condition are vital for smooth operations. Proper beater blade maintenance ensures it stays clean and functional, preventing buildup that can hinder mixing efficiency. A well-maintained blade consistently stirs the ingredients, promoting even freezing and preventing ice crystal formation. If the beater blade becomes dull or damaged, it won’t mix effectively, leading to uneven texture and possible machine strain. Regular inspection and timely replacement keep the blade in prime shape, ensuring your machine operates smoothly and produces high-quality ice cream. Additionally, choosing the right maintenance practices for your equipment can improve its longevity and performance. Using proper maintenance practices can further extend the life of your beater blade and other machine components. By prioritizing beater blade maintenance, you maximize mixing efficiency, reduce downtime, and guarantee your business delivers consistently delicious products.

The Role of the Thermostat in Maintaining Perfect Temperature

A thermostat plays a crucial role in keeping your ice cream at the ideal serving temperature by actively regulating the machine’s cooling cycle. Proper thermostat calibration guarantees it responds accurately to temperature changes, preventing unwanted temperature fluctuation. If the thermostat isn’t calibrated correctly, your machine might cool too much or too little, leading to inconsistent texture or melting issues. Regular checks and adjustments help maintain precise control, so your ice cream stays perfectly frozen but scoopable. A reliable thermostat prevents overcooling, reducing energy waste and equipment strain. Additionally, vital maintenance practices ensure long-term performance and reliability of your refrigeration system. Consistent monitoring of temperature fluctuations is essential to avoid unexpected downtime and maintain product quality. By monitoring and managing temperature fluctuations, you ensure excellent product quality and customer satisfaction. Advances in automation’s role in business intelligence could further optimize thermostat responsiveness for even better temperature regulation. Proper thermostat maintenance is essential for smooth operation and avoiding costly repairs caused by temperature inconsistencies.

Significance of the Seals and Gaskets for Preventing Leaks

Seals and gaskets are critical components that keep your ice cream machine leak-free by creating an airtight barrier between moving parts and external elements. Their seal durability directly affects your machine’s performance and prevents messy spills. Proper gasket maintenance ensures these parts remain effective, avoiding costly repairs or downtime. When seals and gaskets wear out, leaks can lead to contamination or product loss. To maximize their effectiveness, inspect them regularly for cracks or deterioration. Keep in mind:

- Regularly check for cracks or signs of wear

- Replace gaskets showing damage promptly

- Clean seals and gaskets to prevent buildup

- Use compatible materials to maintain seal integrity

- Maintaining seal longevity through proper care can prolong the lifespan of your equipment. Additionally, understanding the types of seal materials can help you choose the most durable options for your specific machine needs. Regular seal inspection and maintenance are essential to prevent unexpected failures. Focusing on seal durability and gasket maintenance guarantees your machine stays leak-free, saving you time and money while ensuring quality service for your customers.

The Benefits of Regularly Replacing the Dispensing Valve

Regularly replacing the dispensing valve plays a vital role in maintaining your ice cream machine’s essential performance. Following proper maintenance schedules ensures the valve functions smoothly, preventing clogs and leaks that could compromise product quality. Consistent replacement minimizes downtime and reduces the risk of costly repairs down the line. Conducting a cost benefit analysis shows that investing in new valves periodically can save you money by avoiding major overhauls or replacements caused by neglect. This proactive approach keeps your machine running efficiently, maintains equipment longevity, and ensures customer satisfaction. Additionally, using high-quality parts and components can further enhance the durability and reliability of your machine. Proper maintenance practices can also help avoid malfunctions that lead to extended downtime and customer dissatisfaction. Ultimately, regular valve replacements protect your investment, improve operational reliability, and help you deliver high-quality ice cream every time.

Frequently Asked Questions

How Often Should Ice Cream Machine Parts Be Inspected for Wear?

You should inspect your ice cream machine parts regularly to prevent breakdowns. A proper inspection schedule involves checking critical components weekly, especially during peak seasons. Incorporate preventive maintenance by examining wear on augers, gaskets, and seals every 1-3 months. Staying consistent with these inspections helps catch issues early, ensuring your machine runs smoothly and efficiently, reducing costly repairs and downtime.

Can Replacement Parts Improve Ice Cream Quality?

Ever wondered if replacement parts could boost your ice cream’s flavor? They definitely can! Upgrading worn components guarantees your machinery runs smoothly, maintaining consistent quality and preventing flavor contamination. Plus, quality parts extend machinery longevity, saving you money long-term. Don’t settle for mediocre ice cream—invest in the right parts to enhance flavor and keep your equipment in top shape. Isn’t your business worth the best?

What Are Common Signs of a Failing Compressor?

You should watch for signs of compressor failure, like strange noises, frequent cycling, or reduced cooling. Refrigerant leaks often accompany compressor issues, causing ice cream to melt faster or not freeze properly. If you notice increased energy bills or inconsistent product quality, your compressor might be failing. Catching these signs early helps prevent costly repairs and keeps your ice cream fresh and delicious, ensuring smooth operations.

How Does Temperature Affect Ice Cream Consistency?

Temperature greatly impacts your ice cream’s texture because it determines the freezing point. When the temperature is too high, the ice cream becomes soft and meltable, while too low makes it icy and hard. Maintaining a consistent temperature guarantees a smooth, creamy consistency. By controlling the temperature, you help the ice cream stay at the best freezing point, resulting in ideal texture and preventing unwanted changes in your product.

Are There DIY Maintenance Tips for Ice Cream Machine Parts?

You can perform DIY cleaning on your ice cream machine parts regularly to keep them functioning smoothly. Start by disassembling removable parts and washing them with warm, soapy water. Use a soft brush to remove buildup, then rinse thoroughly. Apply lubricant where needed, guaranteeing proper lubricant application to moving parts to prevent wear. Regular maintenance like this helps extend your machine’s lifespan and ensures consistent ice cream quality.

Conclusion

By understanding these essential parts—compressors, beater blades, thermostats, seals, and dispensing valves—you protect your equipment, ensure quality, and keep your business running smoothly. Regular maintenance prevents breakdowns, preserves product integrity, and saves you money. When you prioritize these components, you promote efficiency, extend lifespan, and boost customer satisfaction. Stay proactive, stay attentive, and keep your ice cream machine in top shape—because your success depends on it.