Choosing between air-cooled and water-cooled machines depends on your space, budget, and cooling needs. Air-cooled systems are simpler, cheaper, and easier to install, making them ideal for small or less demanding setups. Water-cooled units are more efficient, quieter, and better for high-performance applications but require more space and maintenance. To make the best choice, consider your environment and long-term goals—more details will help you decide which system suits you best.

Key Takeaways

- Water-cooled systems offer higher heat transfer efficiency and quieter operation, ideal for high-demand or continuous use environments.

- Air-cooled units are simpler, less expensive, and quicker to install, suitable for space-constrained or less demanding applications.

- Water cooling requires regular maintenance, monitoring for leaks, and more space for radiators, while air cooling is more maintenance-free.

- Consider environmental impact: water cooling uses more water but provides better cooling; air cooling consumes less energy and water.

- Choose based on your space availability, budget, performance needs, and willingness to maintain complex systems.

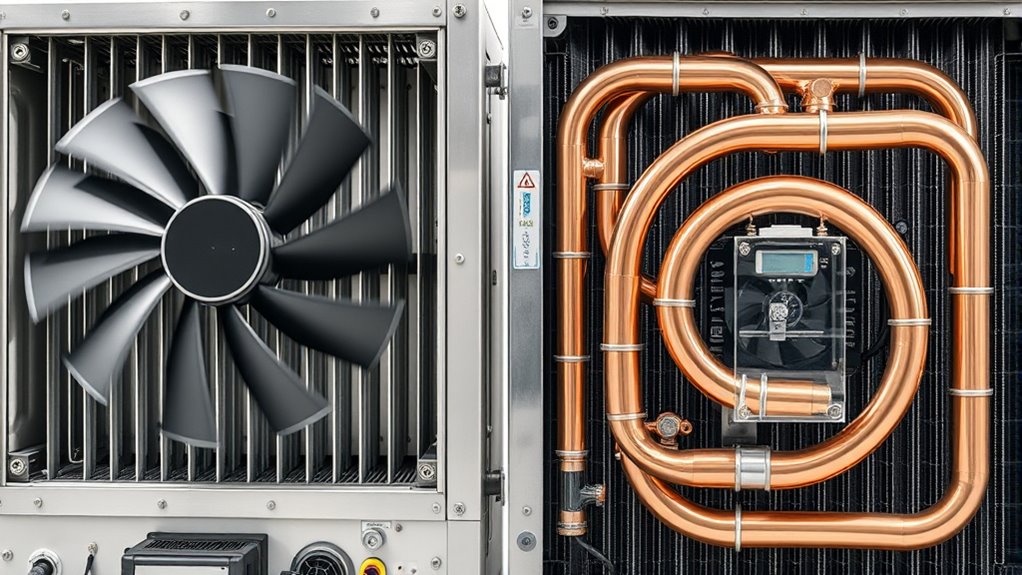

Understanding How Air-Cooled Systems Work

Air-cooled systems rely on fans and fins to dissipate heat from the machine’s components. You’ll notice a cooling fan often positioned to draw air across the fins, which increases air circulation around critical parts. As the fan spins, it pushes cool air over the metal fins, absorbing heat and carrying it away from the system. This process prevents overheating and maintains *ideal* performance. The fins serve as heat sinks, spreading heat across a larger surface area for better dissipation. With proper airflow, your machine stays cool even during intensive use. Proper airflow management is *crucial* in this setup, ensuring consistent cooling and avoiding hot spots. Additionally, regular cleaning of the fins and fan blades helps maintain cooling efficiency, preventing dust buildup that can hinder airflow. Proper maintenance of fans and fins is essential to prevent cybersecurity vulnerabilities, which can sometimes be exploited through hardware manipulation or physical access. Ensuring the hardware components are kept in good condition further supports optimal cooling performance. Furthermore, using high-quality fans can improve thermal regulation and extend the lifespan of your equipment.

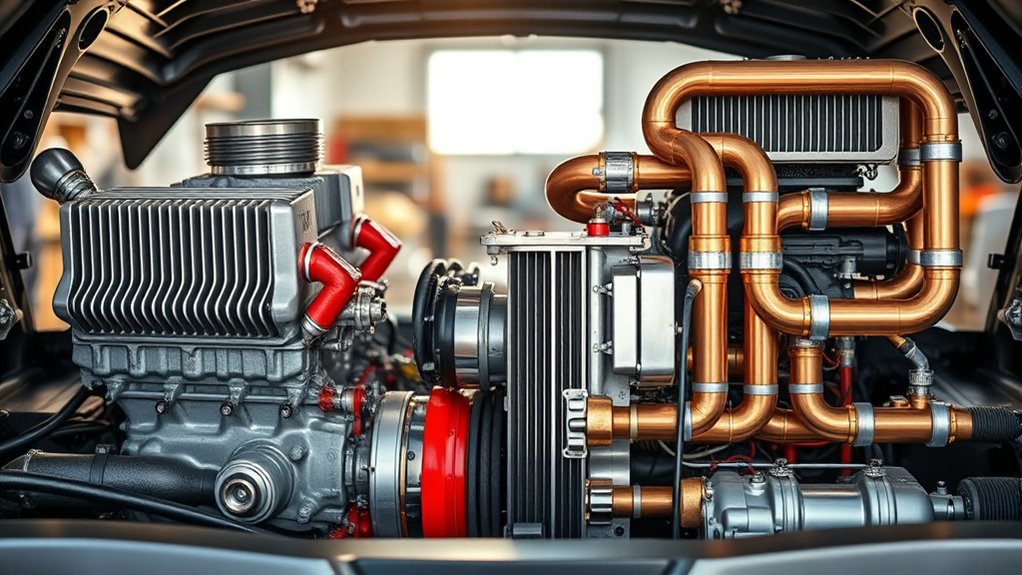

Exploring the Mechanics of Water-Cooled Systems

Water-cooled systems rely on a continuous cooling loop that circulates liquid to remove heat efficiently. You’ll want to understand how the flow dynamics impact heat transfer and overall performance. By exploring these mechanics, you’ll see why water cooling often offers superior heat transfer efficiency compared to air-based solutions. Additionally, the design of traditional butter churns demonstrates how fluid movement enhances separation processes, much like how water flow improves heat dissipation in cooling systems. Understanding the materials used in cooling systems can also influence thermal conductivity and overall system effectiveness. Moreover, the proper management of coolant flow rates is essential to optimize heat removal and prevent system overheating. Properly maintained circulatory systems are critical for consistent operation and longevity of the cooling setup. Incorporating vertical storage solutions can help maintain optimal coolant levels and flow, ensuring consistent performance.

Cooling Loop Dynamics

Understanding the mechanics of water-cooled systems requires examining how the cooling loop operates to transfer heat away from the machine. You rely on fluid flow to move coolant through components, ensuring heat absorption. The coolant’s thermal conductivity is essential, as it determines how efficiently heat is transferred from the heat source to the radiator. A well-designed loop maintains steady circulation, preventing hotspots and optimizing cooling. The pump drives fluid, pushing it through blocks, radiators, and tubing. The process forms a continuous cycle that keeps temperatures stable. To visualize this, consider the following:

| Component | Function |

|---|---|

| Pump | Circulates coolant |

| Radiator | Dissipates heat into the environment |

| Cooling Block | Transfers heat from components to fluid |

Additionally, a properly maintained asset division process ensures that your cooling system operates efficiently and minimizes potential disruptions. Proper maintenance of refrigeration cycle components can further enhance the system’s performance and longevity. Regular inspection of coolant flow dynamics helps identify any blockages or inefficiencies that could impair cooling performance. Furthermore, understanding thermal conductivity of the coolant can help optimize heat transfer efficiency within the loop. Improving fluid flow patterns within the system can also aid in achieving more uniform cooling across all components.

Heat Transfer Efficiency

The efficiency of heat transfer in water-cooled systems hinges on how effectively the coolant absorbs, transports, and releases heat. Water’s high thermal conductivity allows it to quickly transfer heat away from components, making it ideal for cooling. To maximize this, you must focus on airflow optimization around the radiator, ensuring maximum contact and heat dissipation. Proper pump speed and flow rate also play vital roles in maintaining consistent coolant circulation. When airflow is optimized, heat is expelled more efficiently, preventing hotspots. Water’s ability to absorb and carry heat away more effectively than air means your system can run cooler and more reliably. Additionally, understanding the region-specific operating hours can help in planning maintenance or upgrades to your cooling system to minimize downtime. By understanding these mechanics, you can enhance your water-cooled system’s overall heat transfer efficiency.

Comparing Efficiency and Performance

While both air-cooled and water-cooled machines aim to keep components within safe operating temperatures, their efficiency and performance can differ. Water cooling generally provides better heat transfer due to the cooling fluid’s higher thermal capacity, leading to more consistent performance under heavy loads. It also tends to run quieter because noise levels are often lower with water-cooled systems. The automation technologies used in water cooling systems can further optimize thermal management. Water cooling systems often include advanced monitoring features that allow for real-time temperature adjustments, enhancing reliability. Air cooling, however, may struggle with maintaining ideal temperatures during high-demand periods, potentially affecting performance. The table below compares key aspects:

| Aspect | Air-Cooled | Water-Cooled | Notes |

|---|---|---|---|

| Cooling Fluid | Air | Water | Water offers better heat transfer |

| Noise Levels | Higher noise | Quieter | Water cooling reduces noise |

| Efficiency | Moderate | High | Water cooling is more efficient |

| Performance Stability | Less consistent | More consistent | Especially under load |

Assessing Cost and Installation Expenses

When comparing air-cooled and water-cooled machines, you’ll want to contemplate installation complexity and initial costs. Water-cooled systems typically require more extensive setup, which can increase your upfront expenses. Understanding these factors helps you choose the most cost-effective option for your needs. Additionally, considering the side effects of juice detox can provide insights into the importance of proper health management during such routines. Proper maintenance requirements also differ, with water-cooled systems often needing more diligent coolant management to ensure optimal performance. Regularly monitoring the brand reputation of the equipment can help prevent issues related to counterfeit or substandard components. Incorporating natural elements into your setup can further enhance sound healing efficiency and longevity of the system.

Installation Complexity

Choosing between air-cooled and water-cooled machines considerably impacts installation costs and complexity. The installation procedures differ markedly, affecting setup challenges you’ll face. Water-cooled systems often require plumbing, pumps, and additional space, making setup more complex. Air-cooled units typically involve straightforward placements, reducing time and effort. Consider these factors:

- Plumbing and piping requirements for water-cooled systems

- Space needed for additional components

- Potential need for professional installation services

- Complexity of integrating cooling systems into existing setups

- Maintenance considerations during installation

These elements influence the overall difficulty and cost of installation. Water-cooled machines tend to demand more detailed planning and resources upfront, whereas air-cooled options offer a simpler, quicker setup—crucial factors when evaluating your installation challenges.

Initial Investment Cost

Initial investment costs for air-cooled and water-cooled machines can vary considerably, impacting your budget and planning. Conducting a thorough cost analysis helps you compare upfront expenses accurately. Generally, air-cooled systems tend to have lower initial costs because they require simpler installation and fewer components. Water-cooled units, on the other hand, often involve higher costs due to additional equipment like cooling towers, pumps, and plumbing. Market availability also influences pricing; widely available air-cooled options may be be more affordable and easier to source. Keep in mind that while water-cooled systems might have higher upfront expenses, their efficiency could lead to savings over time. Evaluating both purchase price and installation expenses ensures you select the best fit for your financial plan. Lifestyle considerations, such as maintenance requirements and long-term operational costs, are also important factors to weigh during your decision-making process.

Maintenance and Longevity Considerations

Maintaining air-cooled and water-cooled machines requires different approaches to guarantee ideal performance and longevity. With water-cooled systems, you need to monitor corrosion resistance and prevent leaks, as corrosion can cause costly damage. Regularly check coolant levels and replace fluids to avoid buildup that increases noise levels and reduces efficiency. Air-cooled machines demand less maintenance but still require dust and debris removal to prevent overheating.

Maintaining cooling systems involves monitoring for corrosion, leaks, and debris to ensure optimal performance and durability.

- Schedule routine inspections for leaks or corrosion

- Keep cooling systems clean and free of debris

- Use corrosion-resistant materials where possible

- Monitor noise levels for signs of wear or imbalance

- Replace worn components promptly for extended lifespan

Environmental Impact and Sustainability

When considering environmental impact, you should look at how efficiently these machines use energy and resources. Water usage is a key concern, especially with water-cooled systems that can consume large amounts of water. Exploring eco-friendly alternatives can help reduce your carbon footprint and support sustainability efforts.

Energy Efficiency Comparison

While both air-cooled and water-cooled machines aim to optimize performance, their energy efficiencies and environmental impacts differ markedly. Water cooling generally offers better heat dissipation thanks to higher thermal conductivity, allowing for more efficient heat removal. This can reduce energy consumption, especially under heavy loads. Air cooling, while simpler, often requires fans that consume additional power and may struggle with heat dissipation in high-temperature environments. To understand their sustainability, consider:

- Water cooling’s potential for lower energy use due to superior heat transfer

- The environmental impact of refrigerants or coolants in water systems

- The energy costs of fans in air-cooled setups

- How ambient temperature influences heat dissipation efficiency

- Long-term operational energy savings versus initial setup costs

Your choice depends on balancing energy efficiency with environmental considerations.

Water Usage Concerns

Water cooling systems excel at removing heat more efficiently than air-based options, but they can also raise significant environmental concerns related to water usage. Using a cooling fluid requires continuous water intake, which can strain local water resources, especially in areas facing water scarcity. If not managed properly, water consumption can lead to waste and impact water conservation efforts. Additionally, some systems may discharge heated water back into the environment, affecting local ecosystems. To mitigate these issues, you should consider water recycling or reuse solutions and select systems designed for minimal water consumption. Being mindful of water usage helps reduce environmental impact and supports sustainability, making water-cooled machines more eco-friendly when used responsibly.

Eco-Friendly Alternatives

To promote environmental sustainability, many are turning to eco-friendly alternatives that reduce the ecological footprint of cooling systems. These options focus on harnessing renewable energy sources and prioritizing waste reduction. By choosing energy-efficient designs and sustainable materials, you can minimize your machine’s impact. Consider integrating renewable energy like solar or wind power to cut reliance on fossil fuels. Additionally, systems that optimize waste reduction, such as recycling cooling fluids or repurposing heat, contribute to sustainability.

- Use renewable energy sources to power cooling systems

- Select machines with low energy consumption

- Implement waste reduction strategies for cooling fluids

- Opt for environmentally friendly refrigerants

- Prioritize durable materials to extend lifespan and minimize waste

Space Requirements and Setup Flexibility

When choosing between air-cooled and water-cooled machines, understanding their space requirements and setup flexibility is essential. Air-cooled machines generally need less space and are easier to install indoors since they rely on ambient air for cooling. This makes them suitable if you need a compact setup or plan to place the equipment in tight spaces. Water-cooled machines, on the other hand, often require additional room for the cooling system, including radiators and reservoirs, which can limit indoor placement options. They tend to be less portable because of their more complex setup. If portability is a priority, air-cooled units usually offer more flexibility, allowing for easier relocation. Your choice depends on available space and how much setup flexibility you need.

Suitability for Different Industrial Applications

Choosing the right cooling system depends heavily on the specific industrial application. Air-cooled systems excel in environments like residential HVAC, where simplicity and lower upfront costs matter. They are also suitable for automotive cooling, providing quick heat dissipation in engines. Water-cooled systems are better for high-demand settings, such as large manufacturing processes, where consistent temperature control is critical. Consider these factors:

- Automotive cooling benefits from water-cooled systems due to their efficiency in managing engine heat.

- Residential HVAC systems typically favor air-cooled units for ease of installation and maintenance.

- Heavy-duty applications requiring continuous operation often need water-cooled systems.

- Environments with limited space may prefer air-cooled options for their compact design.

- Industrial settings demanding precise temperature regulation lean toward water-cooled solutions.

Matching your application’s needs assures ideal performance and longevity.

Troubleshooting Common Issues

Common issues with air-cooled and water-cooled systems can disrupt performance and lead to costly repairs if not addressed promptly. Noise levels are a frequent concern; excessive noise may indicate loose components or failed fans in air-cooled units, while water-cooled systems might produce vibrations or hissing sounds from leaks or pump failures. Additionally, aesthetic design can be affected by overheating or corrosion, which may cause visible damage or discoloration. Regular inspection helps identify clogged vents, dirty radiators, or leaks early. Ensuring proper airflow and coolant levels is crucial. Addressing these issues quickly can restore peak operation, reduce noise disturbances, and maintain the machine’s visual appeal. Proper troubleshooting preserves efficiency and extends your equipment’s lifespan.

Making the Best Choice for Your Needs

Deciding between air-cooled and water-cooled systems depends on your specific needs, environment, and budget. To make the best choice, consider factors like cooling system materials, which impact durability and maintenance. Water-cooled systems often require more complex setup but excel in noise level comparison, offering quieter operation. Think about your space constraints—air-cooled units are typically simpler to install, while water-cooled systems may need additional plumbing. Evaluate your tolerance for ongoing maintenance and potential leaks versus the longevity and efficiency of each option.

- Noise level comparison: quieter or louder operation

- Cooling system materials: durability and cost

- Space requirements: compact or bulky design

- Maintenance needs: frequent or minimal

- Budget considerations: upfront versus long-term costs

Frequently Asked Questions

Which Cooling System Is Quieter During Operation?

When comparing cooling systems, you’ll notice differences in noise level and operational quietness. Water-cooled machines tend to be quieter because they use a closed-loop system that reduces fan noise and vibrations. Air-cooled units often generate more noise due to larger fans needed for airflow. If you prioritize a quieter environment, a water-cooled system is usually the better choice, offering smoother, less disruptive operation.

Can Air-Cooled Systems Operate Effectively in High Humidity?

In high humidity, air-cooled systems can face humidity challenges that affect cooling efficiency. Moist air hampers heat dissipation, making it harder for air-cooled units to operate effectively. You might notice reduced performance and increased energy use. To guarantee effective cooling, consider whether your environment’s humidity levels are manageable or if water-cooled systems, which handle humidity better, might be a more reliable choice for your needs.

Are Water-Cooled Machines More Energy-Efficient Long-Term?

Thinking of water-cooled machines as the marathon runners of cooling systems, you’ll find they’re generally more energy-efficient long-term. They tend to have lower energy consumption because they maintain stable temperatures, reducing strain. However, you should consider maintenance costs, which are higher due to the complexity of water circulation and potential leaks. Overall, if you prioritize efficiency and are prepared for upkeep, water-cooled options could save you money over time.

How Do Cooling Methods Impact Machine Lifespan?

Cooling methods considerably impact your machine’s lifespan by affecting thermal regulation and maintenance needs. Water-cooled systems typically provide better thermal regulation, preventing overheating and reducing wear on components, which can extend your machine’s durability. However, they require more maintenance to check for leaks and coolant levels. Air-cooled machines may need less upkeep but might struggle with thermal regulation in high-heat environments, potentially shortening lifespan if not properly managed.

Which System Is Easier to Retrofit Into Existing Setups?

Retrofitting a cooling system is like fitting a new suit—you want it to be seamless. Water-cooled systems often involve more retrofitting challenges and installation complexity because they require plumbing and additional components. Air-cooled setups are generally easier to retrofit, with fewer modifications needed. You’ll find them more straightforward to install into existing setups, saving you time and reducing potential complications during the upgrade process.

Conclusion

Choosing between air-cooled and water-cooled machines isn’t just about specs — it’s about your unique needs. Will you prioritize simplicity or precision? Think of your cooling system as the heartbeat of your operation; pick the right one, and watch your performance thrive. Remember, the right choice isn’t just a matter of cost, but of what keeps your machine running smooth and your business flowing seamlessly. So, which will you trust to power your success?