To avoid costly mistakes when installing your ice cream machine, choose a location that promotes visibility and easy access, and guarantee the surface is stable and level. Make sure electrical connections meet safety standards, and verify the refrigeration system’s compatibility. Proper assembly, correct leveling, and adequate ventilation are essential, along with setting accurate temperature controls. Following these steps carefully will help ensure smooth operation—keep going to discover more critical tips for a safe, reliable setup.

Key Takeaways

- Choose a spacious, accessible site near signage to attract customers and ensure good flow.

- Follow manufacturer instructions carefully during assembly, securing all connections to prevent leaks and malfunctions.

- Use dedicated, properly grounded electrical circuits with surge protection and verify refrigerant compatibility.

- Level the machine accurately with a spirit level and ensure proper ventilation to prevent overheating.

- Conduct routine inspections, calibrate temperature controls, and perform test runs to maintain optimal performance.

Choosing the Right Location for Your Machine

Choosing the right location for your ice cream machine is crucial to guarantee smooth operation and customer satisfaction. Positioning it near attractive decorative signage draws attention and encourages impulse purchases. Make sure the spot promotes good customer flow, allowing patrons to easily approach and see the machine without congestion. Avoid placing it in cramped corners or behind obstacles that hinder visibility or accessibility. A well-placed machine boosts sales and creates a welcoming atmosphere. Consider the surrounding space, ensuring there’s enough room for staff to serve efficiently and customers to queue comfortably. The right location balances visibility, accessibility, and aesthetics, helping your ice cream business thrive. Additionally, understanding the importance of proper site planning can prevent costly mistakes and optimize your setup. Incorporating elements of personality insights can help tailor the environment to your target customer base, enhancing their overall experience. Paying attention to automation technology in your placement can also improve your operational efficiency and customer satisfaction. Proper spacing and layout are essential to prevent crowding and ensure smooth workflow, ultimately contributing to a better customer experience.

Ensuring Proper Electrical Connections and Power Supply

To guarantee your ice cream machine operates safely and efficiently, you must establish proper electrical connections and secure a reliable power supply. Make certain all wiring meets electrical safety standards to prevent hazards. Use a dedicated circuit to avoid overloads that could damage the machine or cause outages. Installing a surge protector is essential for power surge protection, shielding your equipment from voltage spikes that can harm internal components. Double-check that connections are tight and grounded correctly, reducing the risk of electrical faults. Avoid extensions cords or temporary wiring, which can compromise safety and stability. Regularly inspect electrical components for wear or damage, and consult a professional electrician if needed. Proper electrical setup not only safeguards your investment but also ensures consistent, safe operation. Additionally, understanding the importance of electricity safety standards helps prevent potential accidents and enhances overall system reliability. Always ensure that your electrical connections comply with local appliance safety regulations to prevent violations and ensure optimal performance. Ensuring proper grounding and adherence to electrical codes can further prevent dangerous faults and improve system longevity. Furthermore, following installation guidelines provided by manufacturers can help avoid common wiring mistakes and optimize machine performance. Being aware of electrical safety standards ensures your setup remains compliant with legal and safety requirements, reducing liability and potential penalties.

Leveling Your Ice Cream Machine Correctly

Making certain your ice cream machine is properly leveled is essential for peak performance and consistent product quality. When the machine isn’t level, it can cause uneven mixing, poor machine calibration, and issues with cleaning procedures. To achieve proper leveling:

- Use a spirit level to check side-to-side and front-to-back alignment

- Adjust the machine’s feet or casters as needed

- Confirm the levelness after each adjustment

- Regularly recheck the leveling, especially after cleaning procedures or maintenance

- Ensure the surface beneath the machine is even and stable

- Incorporate data-driven strategies to monitor and maintain optimal machine performance over time

- Implementing lifecycle maintenance practices can help in maintaining consistent operation and quality.

Proper leveling helps prevent mechanical issues and ensures your machine operates smoothly. It also supports accurate calibration, which directly impacts product consistency. Taking the time to level your machine correctly saves you from costly repairs and quality problems down the line.

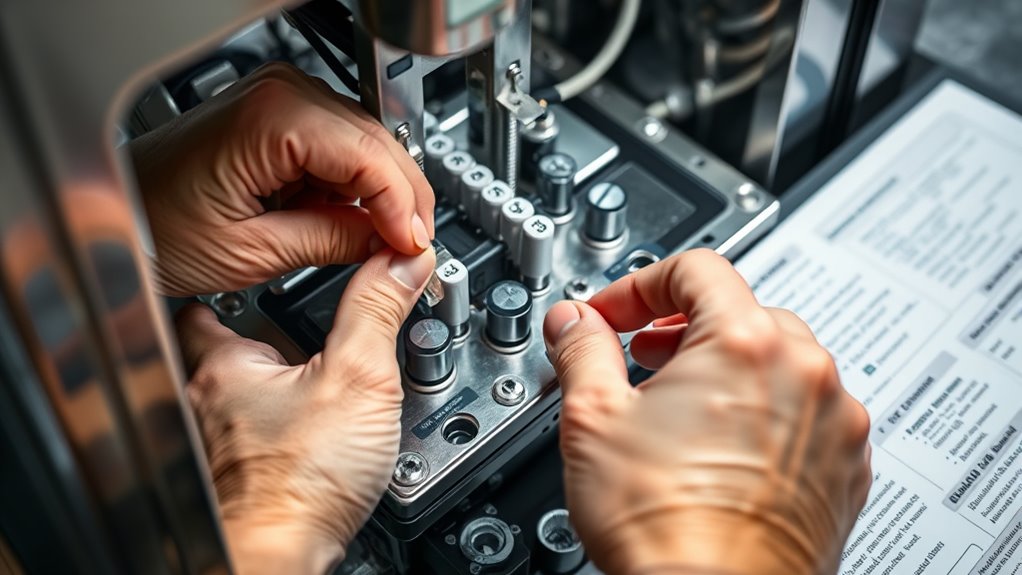

Properly Assembling and Connecting Components

Before assembling your ice cream machine, double-check that all components are compatible. Follow the manufacturer’s instructions closely to guarantee proper fit and function. Make sure to tighten all connections securely to prevent leaks and ensure safety. Being aware of resources and tools available can help you troubleshoot and avoid common installation mistakes. Additionally, verifying the manufacturer’s guidelines can prevent incorrect assembly and potential damage. Understanding proper maintenance practices can extend the lifespan of your machine and ensure consistent performance. Consulting regulatory standards related to appliance safety can also help ensure your installation complies with legal requirements. Reviewing water safety protocols can further help prevent issues related to water-related components or leaks.

Check Component Compatibility

When assembling your ice cream machine, verifying that all components are compatible is essential for a smooth setup. Ensuring compatibility prevents issues during operation and simplifies cleaning procedures later. Check that electrical connections match the machine’s specifications, and confirm that mechanical parts fit correctly. Review the manufacturer’s instructions for any specific requirements. Properly trained staff should double-check component compatibility before installation. Additionally, understanding the self watering plant pots mechanism can help identify compatible parts and prevent mismatches during assembly. It is also helpful to be familiar with electrical standards to ensure safe and proper connections. Being aware of component specifications can help troubleshoot potential issues early on. For example, recognizing the importance of rainwater capture techniques can aid in maintaining your water supply system. Moreover, incorporating self-awareness about the machine’s operation can assist in early detection of potential malfunctions. Key points to consider include: – Electrical voltage and plug type – Mechanical fit of dispensing and mixing parts – Compatibility of cleaning accessories – Compatibility with existing power sources – Staff training on recognizing incompatible parts Taking these steps ensures your setup is efficient, safe, and easy to maintain, minimizing costly mistakes and downtime.

Follow Assembly Instructions Carefully

Careful adherence to assembly instructions is essential for a successful installation. Follow each step precisely to guarantee all components are properly connected and aligned. Skipping or rushing through instructions can lead to problems down the line, like leaks or malfunctions. As you assemble, keep the recommended cleaning schedule in mind, as proper cleaning during setup helps prevent future issues. Once assembled, provide thorough customer training, emphasizing the importance of following assembly guidelines for best operation. Proper assembly not only assures the machine runs smoothly but also makes maintenance and cleaning easier. Double-check connections and alignments as you go to avoid costly repairs later. Taking your time and following instructions carefully guarantees a reliable setup and a satisfied customer. Recognizing signs of proper alignment during installation can prevent issues related to misconnection or imbalance.

Secure Connections Tightly

Ensuring all connections are tightened properly is essential for the ice cream machine’s peak performance. Loose fittings can cause leaks, contamination, or system failures. To prevent this, double-check every hose, valve, and electrical connection after assembly. Properly secured connections also simplify cleaning schedules, reducing bacteria buildup. Train staff on correct tightening techniques to avoid over-tightening or damage. Regularly inspect connections during routine maintenance to catch issues early. Remember, secure connections ensure consistent operation and product quality. Here’s what to focus on:

- Tighten all hoses and fittings according to manufacturer instructions

- Use appropriate tools to avoid stripping threads

- Train staff on proper connection techniques

- Schedule routine inspections for leaks or loose parts

- Document connection checks during cleaning schedules

Following these steps keeps your machine running smoothly and minimizes costly mistakes.

Maintaining Adequate Ventilation and Airflow

Maintaining proper ventilation and airflow is essential for the efficient operation of your ice cream machine. Good airflow prevents overheating and ensures the refrigeration system works effectively. To achieve airflow enhancement, regularly check that ventilation systems are clear of dust, debris, and obstructions. Position your machine in a well-ventilated area, avoiding tight or enclosed spaces that restrict airflow. Use fans or exhaust systems if necessary to improve air circulation. Proper ventilation also helps dissipate heat generated during operation, reducing the risk of system failure. Keep vents clean and unobstructed, and ensure the surrounding environment maintains good air exchange. By prioritizing ventilation and airflow, you extend your machine’s lifespan and maintain ideal performance, avoiding costly breakdowns and downtime.

Verifying Refrigerant and Cooling System Compatibility

Before installing or servicing your ice cream machine, it’s essential to verify that the refrigerant type and cooling system are compatible. Using the wrong refrigerant types can cause system failure or inefficiency. Check the manufacturer’s specifications to ensure your cooling system supports the refrigerant you plan to use. Compatibility issues may lead to costly repairs or reduced performance.

Consider these points:

- Confirm refrigerant type matches manufacturer’s recommendations

- Ensure cooling system supports the refrigerant’s pressure and temperature ranges

- Check for compatible components like valves and gauges

- Verify fittings and connections are designed for your refrigerant

- Consult a professional if unsure about refrigerant types or cooling system compatibility

This ensures your ice cream machine runs efficiently and avoids potential damage.

Setting Up Accurate Temperature Controls

Accurate temperature controls are essential for producing quality ice cream and ensuring the machine operates efficiently. To achieve this, you need to follow proper calibration procedures regularly. Use a reliable thermometer to check the temperature settings and compare them to the machine’s display, adjusting as needed. Consistent calibration helps maintain the ideal freezing point, preventing over-freezing or melting. Additionally, sticking to a maintenance schedule ensures your temperature controls stay precise over time. Regularly inspecting sensors and wiring prevents drift in temperature readings. Document calibration results and maintenance actions to track performance. Properly setting up and maintaining your temperature controls minimizes spoilage, improves product consistency, and extends your equipment’s lifespan. Accurate controls are the backbone of smooth, high-quality ice cream production.

Conducting a Test Run Before Full Operation

Conducting a test run is a crucial step to guarantee your ice cream machine is functioning correctly before full operation. It allows you to identify potential issues early, ensuring smooth service later. During the test, focus on flavor testing to confirm the taste and texture meet quality standards. Gather customer feedback from a small group to gauge preferences and make adjustments if needed.

Key steps include:

- Running the machine for the recommended time

- Checking temperature consistency

- Testing different flavors for quality

- Monitoring for unusual noises or malfunctions

- Recording initial customer feedback

This process helps you fine-tune your setup, avoid costly mistakes, and deliver a great product from day one. A thorough test run ensures your machine performs reliably and customer satisfaction remains high.

Frequently Asked Questions

How Often Should I Schedule Professional Maintenance for My Ice Cream Machine?

You should schedule professional servicing for your ice cream machine at least twice a year to guarantee peak performance. Following a proper maintenance schedule helps prevent breakdowns and keeps your machine clean and efficient. Regular maintenance allows you to catch potential issues early, saving money and avoiding costly repairs. Trust a professional to handle the service, as they have the expertise to maintain your machine properly and extend its lifespan.

What Safety Precautions Are Necessary During Installation?

Like a careful navigator, you must prioritize installation safety to prevent hazards. Wear protective gear, such as gloves and goggles, during setup. Make certain electrical connections are secure and grounded properly to avoid shocks. Keep the workspace dry and clear of obstructions, and follow manufacturer instructions closely. Hazard prevention is essential; double-check all components and avoid rushing. These steps help you secure a safe, efficient installation, preventing accidents and costly mistakes.

Can I Install the Machine Outdoors or in a Humid Environment?

You can install your ice cream machine outdoors or in a humid environment, but you need to take extra precautions. Make certain the area is well-ventilated and protected from direct sunlight or rain. Use a weatherproof cover if possible, and make sure the machine is rated for outdoor use. Regularly check for moisture buildup and maintain proper electrical connections to prevent damage. Proper setup guarantees peak performance and longevity.

How Do I Troubleshoot Common Temperature Regulation Issues?

Think of your ice cream machine as a finely tuned orchestra; when it hits a sour note, troubleshooting is key. First, check the temperature sensors—are they dirty or misaligned? Next, listen for compressor issues, like strange noises or failure to cool. Sometimes, resetting the machine or inspecting wiring solves the problem. Regular maintenance keeps the temperature regulation smooth, preventing issues before they start.

What Are the Warranty Requirements Regarding Installation Procedures?

You need to follow the installation guidelines carefully to guarantee warranty compliance. Manufacturers often require that you use approved parts and adhere to specified procedures during installation. Failing to do so could void your warranty, leaving you unprotected if issues arise. Always double-check that your setup meets the warranty requirements, and keep detailed records of the installation process. This way, you safeguard your investment and ensure your warranty remains valid.

Conclusion

By following these steps carefully, you’ll avoid costly mistakes and guarantee your ice cream machine operates smoothly. Skipping proper setup might seem quick and easy, but it can lead to expensive repairs or inconsistent ice cream quality. Investing a little extra time now guarantees reliable performance and longevity. Remember, precision and patience during installation pay off in delicious, perfectly textured ice cream for your customers or family to enjoy.